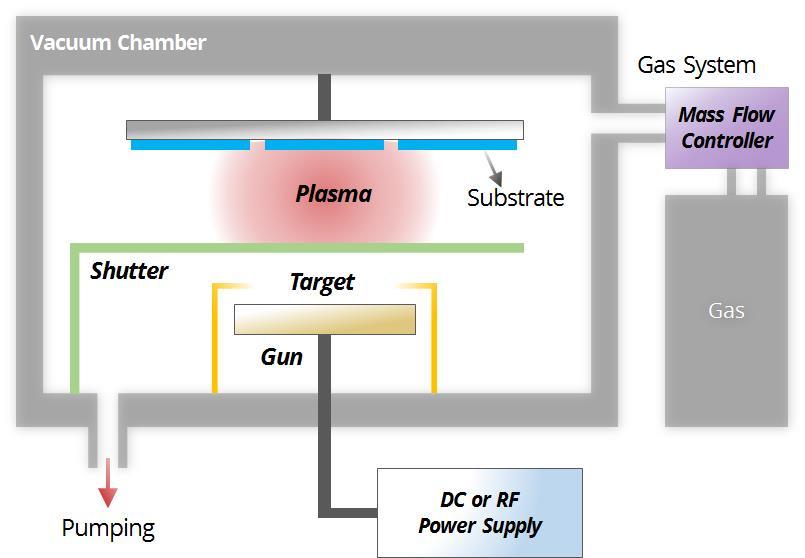

RF/DC Magnetron Sputtering system

Model - Smart Coat 3.0 RF/DC Sputtering System

Make: M/s. Hind Hi Vacuum Systems

Schematic diagram (Image source: https://doi.org/10.1007/s40684-016-0049-8)

Working principle:

When a beam of high energetic ions (typically Ar) bombards a target surface, atoms or molecules from that surface sputter out as a plume. If a substrate is simultaneously place in the path of the plume, these particles will deposit on that, forming films. By controlling various parameters, like time of exposure, discharge voltage, distance between the target and substrate, substrate temperature etc., it is possible to deposit thin films of various nature.

DC sputtering is exclusively used for conducting samples, like metals and alloys. RF sputtering is used mainly for dielectrics. To increase the sputtering rate, magnetic field is generated by placing magnets behind the cathode. This folds the trajectories of ions and electrons to increase the collision probability (i.e. rate) and the sputtering yield is increased.

Uniqueness of this system is that there are six substrate slots available for simultaneously depositing films on multiple substrates. Also, it has provision to introduce reactive gases for creating special films. Finally the sample change can be done in vacuum (load lock chamber system). The whole system is evacuated by a turbo for clean environment. It also has differentially variable speed for uniform coating.

Uses:

There are many uses for this sophisticated instrument, like

- Film deposition: especially for routine variety.

- Etching: for etching the target surface of semiconductors in one of the cleanest ways, and a high degree of etching anisotropy is required.

Photographs of the instrument

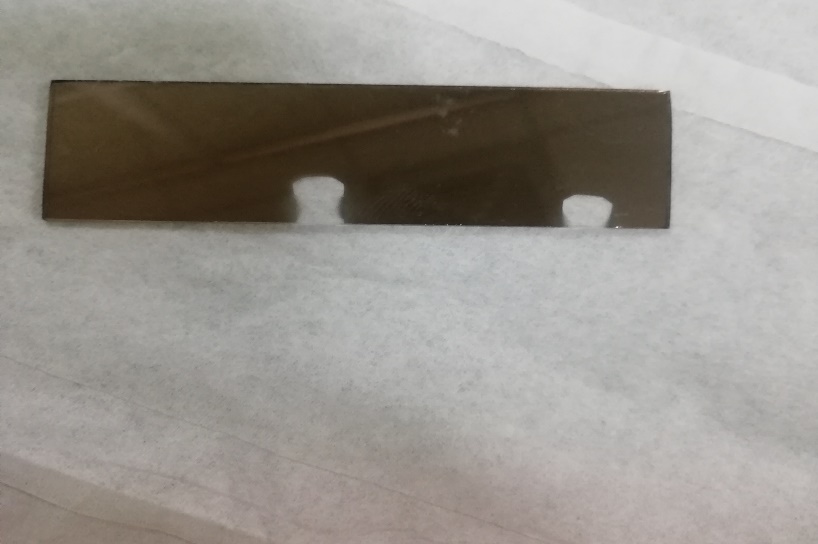

Prepared Samples:

Uniform thin film of aluminium was deposited on a glass surface

Specifications:

Maximum substrate each process, Diameter |

6 Nos, 2 inch. |

Substrate holder diameter |

8 inch |

Substrate holder temperature range |

Room temp - 800ºC |

Source Diameter, max thickness |

2 inch, 6mm |

Z axis motion |

Upto 20mm |

Source material |

Metals or dielectrics |

DC voltage and power |

1 kV, 1 kW |

RF power (13.56MHz) |

RF power (13.56MHz) |

Minimum vacuum |

5x10-7 mPa |

User adjustable magnetron tilt angle |

±45º |

Inline thickness monitor resolution |

0.01 or 0.001 nm/s |

Process gas and vent gas supply:

Process gas- |

|

Gas |

Argon in general, Oxygen, Nitrogen, Hydrogen. |

Flow |

1 - 200 sccm |

Purity |

99.999% pure |

Vent gas |

|

Gas |

Nitrogen |

Pressure |

1.0 bar |

Purity |

Normal commercial grade 'dry' |

Rate:

- Rs. 3,000/- per 50nM of deposition per sample for academic users

- Rs. 3,500/- per 50nM of deposition per sample for industrial users