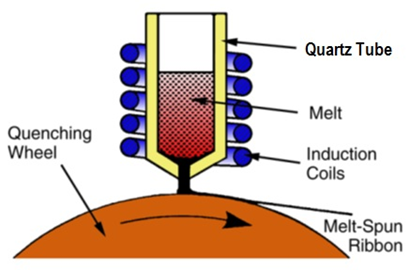

RF Induction and Melt Spinning Furnace

Model - RF Induction furnace with accessories,

Make - M/s. Vacuum Techniques Pvt. Ltd., Bangalore

Schematic diagram (Image source: https://doi.org/10.1007/s12666-015-0657-y)

Working principle:

Induction heating is a process wherein induced eddy currents heat electrically conductive materials (metals and semiconductors). In case of ferromagnetic samples, additional heating occurs through magnetic hysteric effects. In the present system, a powerful RF oscillator feeds a water cooled copper coil that encloses a crucible containing samples. The whole system is kept under vacuum during initial melting. The congruent melting results in homogeneous samples.

Melt Quenching is obtained here by forcing out a small amount of liquid melt directly on the surface of a rotating and water chilled big copper wheel, positioned very near to the orifice of the crucible containing liquid melt. The cooling rate so obtained is about 105 to 106 K/s, high enough to prevent crystallization process of most alloys and even some pure metals, forming amorphous ribbons instead. Ar gas is used here to eject the liquid melt. All the process parameters are set in a remote controlled environment, with overriding manual control for any emergency.

Uniqueness of this system is that total sample needed is very small, in the range of 2 - 12g only. This is absolutely necessary for basic research purpose, where ingredients have 99% or better purity level and so price per gram is very high. This is in contrast to such furnaces available elsewhere, like in engineering departments, where minimum sample size is 500g to 1kg or so, because the sample purity demand is much less, like 95%. Finally, at present we are using quartz crucibles that can withstand up to about 1700ºC, for systems with higher melting point, we have to acquire graphite crucibles which can manage up to about 3000ºC.

Uses:

It is useful for making thin samples of metallic alloys. The rapid quenching allows formation of metallic glasses, completely amorphous in nature and not possible to make otherwise. Additionally, this facility is expressly designed to making research grade samples, with cleanest possible environment for very high purity elements.

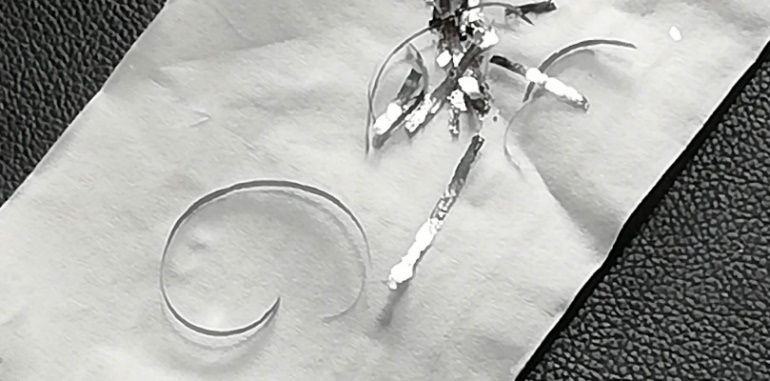

Photographs of the instrument

A typical sample, thickness 10μm, width ~ 3mm and average length of 10cm

Process gas and other parameters:

| Process gas- | |

Gas |

Argon |

Pressure |

1.0 bar |

Purity |

99.999% pure |

Gas ejecting pressure range |

0 to 10 LPM |

Important technical specifications:

Maximum melting temperature |

3000ºC |

Ultimate pressure |

≤ 2.0*10-5 mbar |

Maximum weight range of ingot samples |

2 to 12 grams |

Copper wheel RPM range |

0 to 2800 RPM |

Maximum RF Output power |

15 kW |

Applications:

- Material Sciences

- Semiconductors

- Metal Research and Industry

Rate:

- Rs 3,000/- per sample for academic users

- Rs. 3,500/- per sample for industrial users